In-Depth Analysis of Injection Molding and Blow Molding Processes — Principles Comparison

There’s a story in every cup, warmth in every life. Hello everyone, and welcome to "Dong Dong's Cup Talk" In our recent posts, some friends have privately messaged us asking about the differences between injection molding and blow molding. In fact, comparisons and analyses of these two processes are widely available online, including on a certain well-known search engine — just type in “differences between injection and blow molding,” and you’ll find extensive comparison articles. We don’t need to show off amateur skills in front of experts, but as we’ve mentioned before, https://www.umbottle.com/ProductsDetail-OR-10072.htmlwhenever friends have questions, we’ll do our best to answer them. Especially after reading many online comparison articles, we thought it would be helpful to explain the differences between these two processes in our own way, making it easier for everyone to understand.

In our sharing, we’ll focus on daily necessities, electronic products, and the cup and bottle industry — our area of expertise. https://www.umbottle.com/ProductsDetail-OR-10072.htmlWe’ll explain the process principles, equipment selection, material compatibility, and some case studies in an easy-to-understand manner. We hope you find it helpful. If our content proves useful, please don’t forget to give us a like. And if you want to stay updated with our future posts, be sure to follow us.

Every bit of your support is the driving force behind our tireless efforts. Oh, and by the way, our factory not only produces stainless steel cups but also plastic cups. https://www.umbottle.com/ProductsDetail-OR-10072.htmlWe also handle the production of various plastic molds and process food-grade plastic products. Hahaha, this isn’t an ad — really, it’s not!

I. Comparison of Process Principles and Applicable Scenarios

1. Injection Molding Process

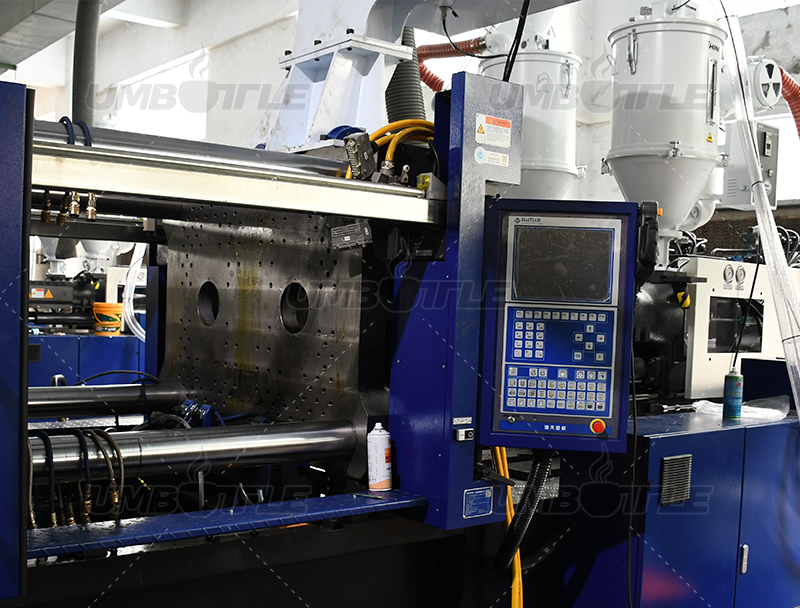

Principle: Molten plastic is injected under high pressure into a closed mold via a screw, cooled to solidify, and then ejected.

Characteristics: Suitable for products with complex structures, https://www.umbottle.com/ProductsDetail-OR-10072.htmlminimal wall thickness variations, and high dimensional accuracy (e.g., gears, cup lids).

Data Support:

- Typical injection molding cycle: 15-120 seconds.

- Clamping force range: 50 to 6000 tons (Source: ENGEL Injection Molding Machine Technical Manual).

2. Blow Molding Process

Principle: A molten plastic parison is formed and then inflated with compressed air to conform to the inner walls of the mold.

Characteristics: Suitable for hollow, thin-walled products with large surface curvatures https://www.umbottle.com/ProductsDetail-OR-10072.html(e.g., bottles, jars, and irregularly shaped containers).

Data Support:

- Typical blow molding cycle: 30-180 seconds.

- Parison thickness tolerance must be controlled within ±5% (ASTM D1998 standard).

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.