In-Depth Analysis of Injection Molding vs. Blow Molding - Material Selection Guide

There's a story in every cup, warmth in every life. Hello everyone, "Dong Dong's Cup Talk" is back! Recently, some friends have DM'd asking about the differences between injection molding and blow molding. While countless comparisons exist online (just search any major engine), I noticed most articles are overly technical. http://www.umbottle.com/ProductsDetail-VB-10332.htmlSo today, I'll break it down my way - focusing on daily products, electronics, and our specialty: drinkware.

Our factory actually handles both processes (plus stainless steel bottles and custom plastic mold development - not an ad, just saying!). http://www.umbottle.com/ProductsDetail-VB-10332.htmlI'll explain key concepts through:

✔ Process principles

✔ Equipment selection

✔ Material compatibility

✔ Real-world cases

If you find this helpful, please like/follow! Your support fuels our content.

3. Scientific Logic of Material Selection

1. Process-Specific Materials

• Injection-Only: POM (fast crystallization, brittle)

• Blow-Only: http://www.umbottle.com/ProductsDetail-VB-10332.htmlHDPE (poor flow but stress-crack resistant)

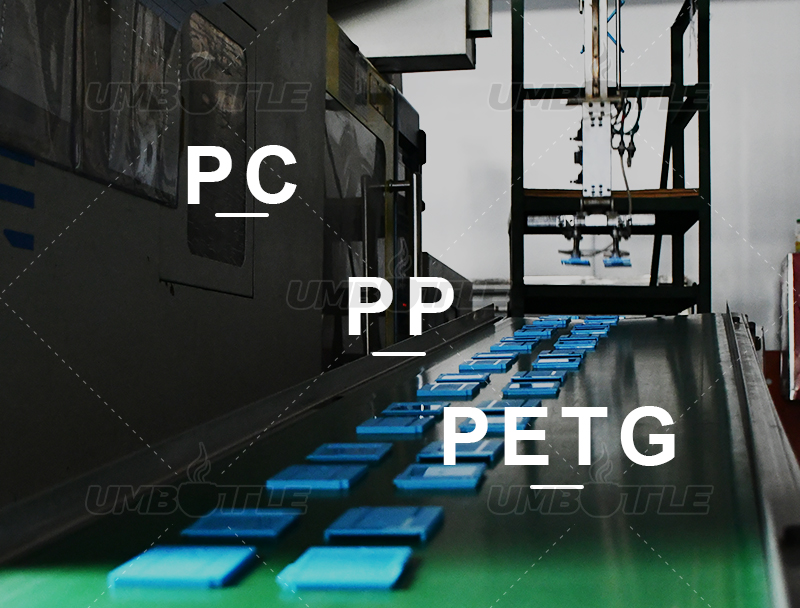

• Dual-Process: PC/PP/PETG (adjust MFI: 20-50g/10min for injection vs. 0.5-3g/10min for blow molding)

Case Study: 12mm Thick Cup Body

• Requirements: -20°C~100°C, >95% yield

• Solution:

- Glass-filled PP (e.g., Sabic PP 514M12, HDT 135°C)

- Parameters: http://www.umbottle.com/ProductsDetail-VB-10332.html80MPa holding pressure, 60°C mold temp (reduces fiber surfacing)

• Result: Shrinkage drops from 1.5% (regular PP) to 0.3%

2. Blow Molding Material Tricks

Case: PCTG Kids' Bottle

Case Study: http://www.umbottle.com/ProductsDetail-VB-10332.htmlPCTG Toddler Water Cup

TX1001 vs. TX2001:

TX1001 (impact strength 1200 J/m) offers superior drop resistance compared to TX2001 (800 J/m).

TX2001 (MFI 12 g/10 min) is easier to mold than TX1001 (MFI 8 g/10 min).

A compromise solution: Using a TX1001 base material with 0.5% silicone masterbatch reduces the molding cycle by 15% while maintaining drop resistance.

Pro Tip: For translucent bottles, http://www.umbottle.com/ProductsDetail-VB-10332.htmlPETG with 3% MBS modifier improves clarity while maintaining drop resistance.

Material selection balances performance vs. manufacturability. Got unique requirements? DM me for tailored solutions!

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.