Injection Molding Principles and Practical Analysis of Multi-Color Cup Component Production (Multi-Color Injection Molding Machine Edition)

There are stories in cups, and warmth in life. Hello everyone, "Dong Dong's Cup Talk" is here.

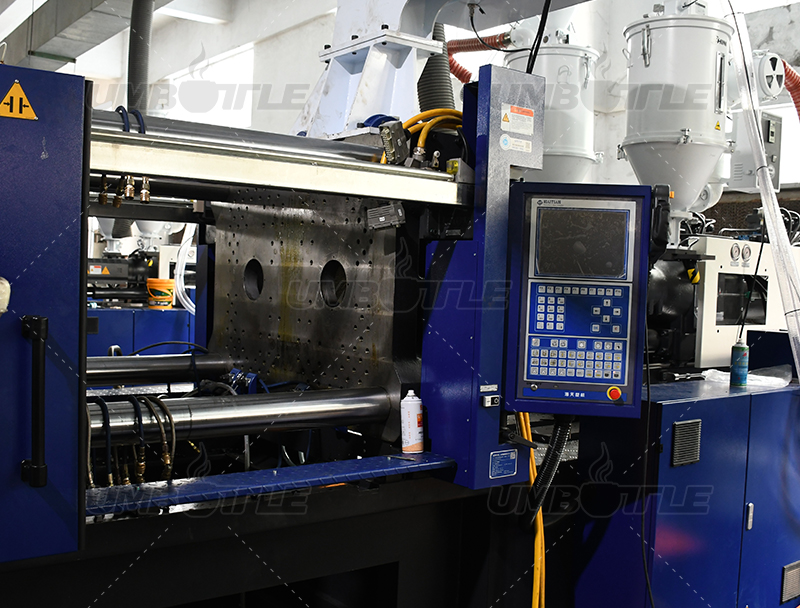

In previous discussions, we mentioned that our factory not only manufactures cups but also specializes in plastic mold production. Since plastic components are essential in cup manufacturing, our facility is equipped with a professional and well-established injection molding department. http://www.zhanyict.com/en/ProductsDetail-VB-10504.htmlToday, drawing from years of hands-on experience and real-world cases, I'll share insights into the principles of injection molding and a practical breakdown of multi-color cup component production. Given the depth of the topic, this will be divided into multiple installments.

III. Practical Challenges in Multi-Color Injection Molding

1. Comparison of Two-Color Injection Molding Machine Types

- Rotary Table Type:

- Principle: Mold rotates 180° for secondary injection.

- Advantage: Lower equipment cost.

- Disadvantage: http://www.zhanyict.com/en/ProductsDetail-VB-10504.htmlPrecision affected

by turntable clearance.

- Applicable Products: Cup lids with hard/soft material combinations (e.g., PP + TPE).

- Simultaneous Type:

- Principle: Two injection systems operate in sync.

- Advantage: Cycle time reduced by 30%.

- Disadvantage: http://www.zhanyict.com/en/ProductsDetail-VB-10504.htmlRequires two independent temperature control systems.

- Applicable Products: Layered cup bodies with transparent + opaque sections (e.g., Tritan + ABS).

2. Four Major Technical Challenges in Multi-Color Injection Molding

① Material Compatibility:

- Hard/soft material interfaces require molecular-level bonding (e.g., PC and TPU need compatibilizers).

- Failure Case: http://www.zhanyict.com/en/ProductsDetail-VB-10504.htmlA two-color cup lid (ABS + silicone) failed due to insufficient interfacial adhesion. Switching to ABS/TPE combination passed 5,000 open-close tests.

② Mold Alignment Precision:

- Coaxiality of two-color cavities must be ≤0.02mm to prevent flash.

- Laser in-mold positioning systems can improve yield rates.

③ Temperature Gradient Control:

- Cooling shrinkage of the first color must match the melt expansion of the second color http://www.zhanyict.com/en/ProductsDetail-VB-10504.html(e.g., Tritan first color at 40°C mold temp, PC second color at 90°C).

④ Runner Balance Design:

- Multi-color molding requires independent hot runner systems to prevent material cross-contamination (critical for food-grade materials).

Would you like any refinements or additional technical details?

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.