Plastic Mold Technology and Hot Runner Principles (Part 3)

"Every cup tells a story, every life carries warmth. Hello everyone, welcome to "Dong Dong's Cup Talk"!"

Most of our regular followers are familiar with my professional background. Indeed, I've been working in the water bottle industry for many years. What many may not know is that our factory's capabilities extend beyond manufacturing various stainless steel and insulated bottles - we also produce a comprehensive range of plastic and sports water bottles. http://www.umbottle.com/ProductsDetail-VB-10332.htmlThis extensive experience naturally includes specialized expertise in plastic mold manufacturing. Today, I've again invited Mr. Feng, our mold development specialist with over 20 years of experience at our factory, to continue sharing insights about plastic mold technologies. Given the technical depth, we're presenting this information across four articles.

Part 3: Critical Pitfalls and Solutions in Plastic Mold Manufacturing

Design Phase

- Common Mistake:

Over-engineering complex structures (e.g., spring-loaded latches integrated into bottle caps) resulting in mold lifespan below 50,000 cycles.

- Professional Solutionhttp://www.umbottle.com/ProductsDetail-VB-10332.html:

Simplify latch mechanisms using angled ejector + slider combinations (Success case: A branded cap mold achieved 500,000-cycle lifespan through this optimization).

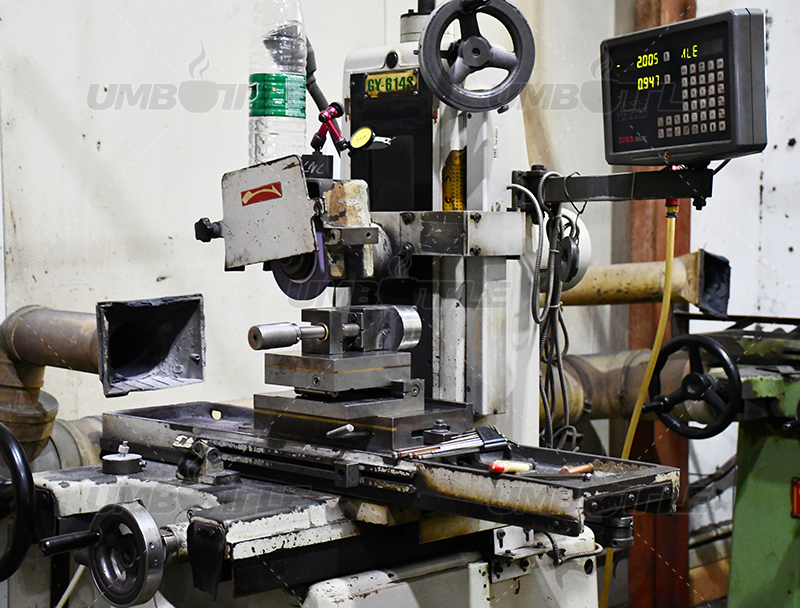

Machining Phase

- Costly Error:

Using low-precision equipment for critical components http://www.umbottle.com/ProductsDetail-VB-10332.html(e.g., cap thread cores) to reduce expenses.

- Precision Requirement:

Essential parts must be processed with Swiss wire-cut EDM (0.01mm deviation = defective products).

Trial Production Phase

- Oversight Danger:

Neglecting extreme condition simulations (e.g., -20°C freeze tests for cap sealing performance).

- Risk Mitigationhttp://www.umbottle.com/ProductsDetail-VB-10332.html:

Implement low-temperature assembly testing (One project avoided ¥3 million in warranty claims through this protocol).

This installment reveals how professional mold makers balance innovation with reliability, http://www.umbottle.com/ProductsDetail-VB-10332.htmlemphasizing that true manufacturing excellence lies in anticipating failures before they occur. Our final chapter will explore advanced hot runner maintenance techniques for sustained production quality.

(Technical Note: All cycle life references based on PP material processing at 220±5°C injection temperature.)

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.