In-Depth Analysis: How the Water Bottle Industry is Adapting to Biodegradable Materials - Mold Modification Chapter

"Every cup tells a story, every life carries warmth. Hello everyone, welcome to "Dong Dong's Cup Talk"!"

With growing environmental awareness in global consumer markets, over 60 countries including China have implemented stricter carbon emission and carbon neutrality standards. These initiatives have significantly increased the adoption of biodegradable materials in daily consumer goods, and the water bottle industry is no exception. http://www.umbottle.com/ProductsDetail-VB-10448.htmlDuring 2024-2025, dozens of brand owners, purchasers, and industry engineers visited our factory to discuss biodegradable material solutions. Through extensive research and DeepSeek analysis, we've compiled the following insights.

This content addresses key considerations for using corn fiber, rice husk fiber, and coffee grounds in water bottle production. What modifications are required for injection molding equipment and molds? Why is PP added during production? Are there alternative materials? http://www.umbottle.com/ProductsDetail-VB-10448.htmlGiven the volume of information, we'll present it in separate articles by material type, hoping to assist professionals seeking this knowledge.

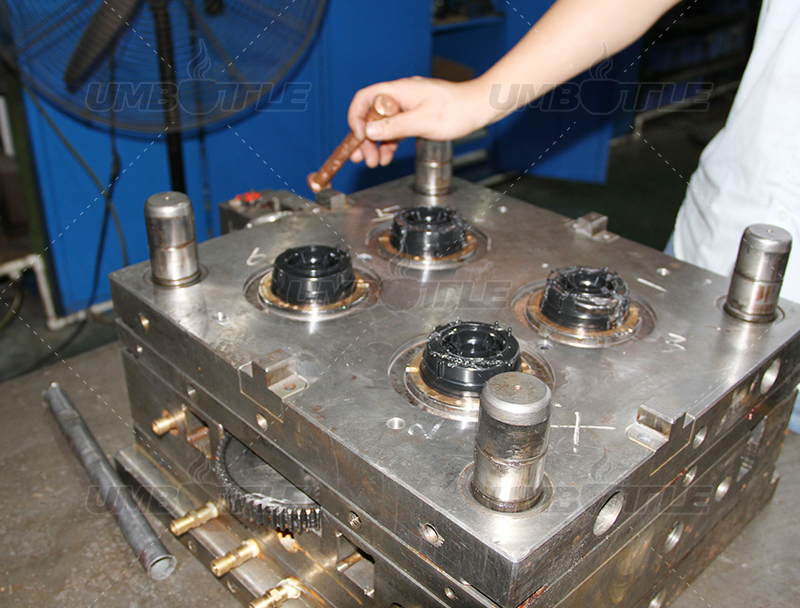

II. Injection Molding Equipment and Mold Modification Requirements

- Screw Design

Standard three-stage → Chrome-plated anti-corrosion screw required (due to PLA acid corrosion)

- Barrel Temperature

200-240°C → PLA: 160-180°C, http://www.umbottle.com/ProductsDetail-VB-10448.htmlCoffee grounds: 170-190°C

- Mold Runner

Conventional cold runner → Increase cross-sectional area by 15-20% (poor flow characteristics)

- Vent Grooves

0.03mm depth → Increase to 0.05-0.08mm (higher gas emission during decomposition)

- Cooling System

Standard water channels →http://www.umbottle.com/ProductsDetail-VB-10448.htmlRequires mold temperature controller with ±2°C precision

Key modifications focus on material-specific processing requirements, with particular attention to temperature control, corrosion resistance, http://www.umbottle.com/ProductsDetail-VB-10448.htmland improved flow characteristics for optimal biodegradable material performance.

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.