What are the defects of internal spraying technology of stainless steel water cups?

Friends, the content I share today is quite contradictory to my profession. I have been engaged in the water cup manufacturing industry for many years. The internal spraying process of stainless steel water cups has only been widely used in the past 5 or 6 years. http://www.zhanyict.com/en/ProductsDetail-VB-10111.htmlMany of the stainless steel water cups produced by my factory in recent years have also adopted internal spraying technology. But now I have to share the defects of the internal spraying technology of stainless steel water cups.

I feel like I am digging a hole for myself. However, I still share the current defects of internal spraying technology with you based on the professional qualities of a professional. The following content only represents my personal opinion. http://www.zhanyict.com/en/ProductsDetail-VB-10111.htmlIf there are colleagues who are accidentally injured, please do not bring them in. If there is any loss, please treat it as my nonsense and do not embarrass me. I am unable to bear any responsibility.

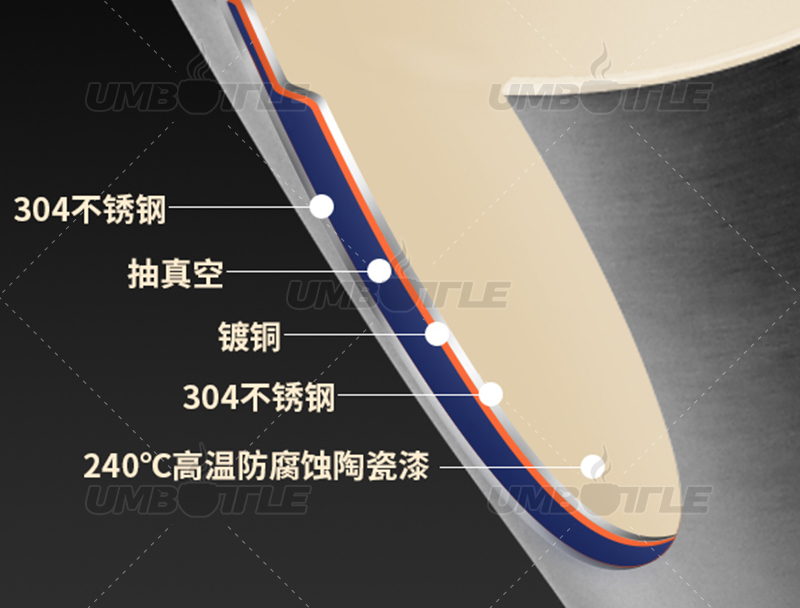

At present, the processes commonly used for the inner wall of stainless steel water cups are: pure polishing, polishing electrolytic sandblasting, spraying ceramic paint and enamel process. I will not go into details about pure polishing and polishing electrolytic sandblasting processes. http://www.zhanyict.com/en/ProductsDetail-VB-10111.htmlThe following focuses on sharing the differences between spraying ceramic paint and enamel processes, and what are the technical defects of each.

Ceramic paint spraying is a common inner wall coating technology in the current water cup market. Internal spraying of ceramic paint is also called imitation ceramic process. http://www.zhanyict.com/en/ProductsDetail-VB-10111.htmlAs the name implies, this treatment will make the inner wall of the water cup look more like ceramic, and it also has the characteristics of a ceramic water cup. The advantage of doing this is that it can improve the corrosion resistance and wear resistance of the inner wall of the stainless steel water cup, and at the same time it can beautify the inner wall of the water cup.

Ceramic paint can be mixed into a variety of colors, but currently the market is mainly white and ivory yellow, and there are also gray, black and cyan, but consumers still mainly buy white and ivory yellow for aesthetic reasons. http://www.zhanyict.com/en/ProductsDetail-VB-10111.htmlAlthough ceramic paint spraying technology is becoming more and more mature, and the performance of imitation ceramic coatings is becoming more and more excellent, due to production management, spraying technology and incomplete implementation of standards, many ceramic paint spraying technologies currently being sold on the market still have some potential technical defects, such as:

Poor adhesion: The adhesion between the ceramic paint and the stainless steel substrate may not be strong enough, and it is easy to peel off.

Poor durability: After long-term use, the ceramic paint layer may be worn and corroded, resulting in reduced durability.

There are many reasons for the above problems, and most of them are caused by production capacity.http://www.zhanyict.com/en/ProductsDetail-VB-10111.html The more standardized the production management and the stricter the quality management, the fewer products will have similar problems.

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.