Key Considerations in PCTG Injection Molding Production

PCTG (Polyethylene Terephthalate Glycol) is a thermoplastic material known for its superior transparency, chemical resistance, and heat resistance. It finds wide applications in areas such as food packaging, medical devices, and household products. http://www.umbottle.com/ProductsDetail-VB-10332.htmlDuring PCTG injection molding production, it is crucial to pay special attention to a series of key issues to ensure product quality, production efficiency, and worker safety.

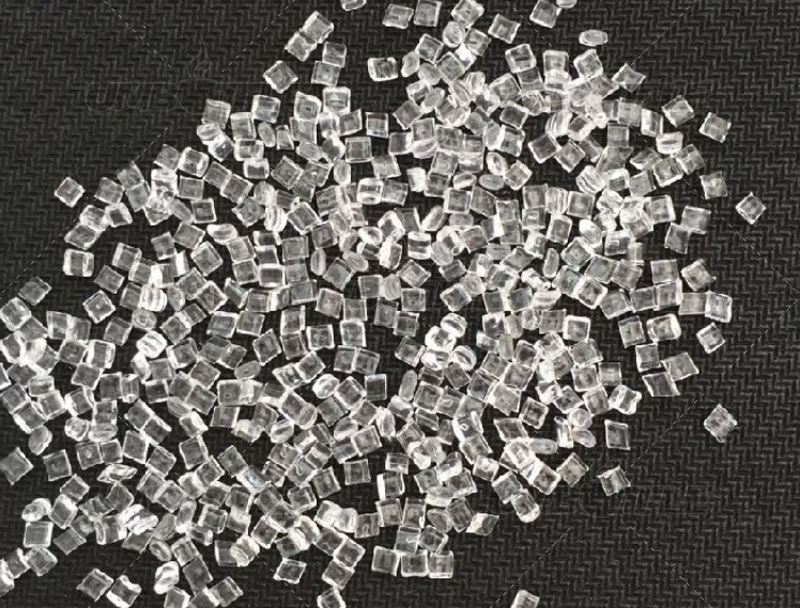

Raw Material Selection and Inspection

Material Quality:

Choose high-quality PCTG raw materials that comply with relevant international and industry standards.

Regularly inspect raw materials to ensure their physical and chemical properties meet requirements.http://www.umbottle.com/ProductsDetail-VB-10332.html

Color and Transparency Control:

PCTG is often used for manufacturing transparent or translucent colored products, requiring careful control of material color and transparency consistency to meet customer demands.

Mold Design and Manufacturing

Optical Surface Design:

PCTG is commonly used for products requiring high optical surface quality.

The design and manufacturing of the mold surface must meet high standards to ensure transparency and appearance quality of the finished product.

Temperature Control:

Properly control temperatures during the injection molding process, including mold temperature and injection temperature, http://www.umbottle.com/ProductsDetail-VB-10332.htmlto prevent degradation of PCTG material and ensure product quality.

Injection Molding Process Parameter Control

Injection Temperature:

PCTG's injection temperature is typically higher, requiring adjustment of temperature parameters based on the material's melt flow characteristics to ensure smooth injection and uniformity of the finished product.

Injection Speed:

Control injection speed to prevent defects such as bubbles and weld lines caused by too rapid injection of the melt into the mold.

Cooling System Design:

Design the injection mold's cooling system effectively to ensure thorough product cooling, avoid excessive internal stress, http://www.umbottle.com/ProductsDetail-VB-10332.htmland enhance the physical properties of the finished product.

Quality Control and Testing

Visual Inspection:

Conduct visual inspections of injection-molded products for defects such as bubbles, weld lines, cracks, etc., ensuring product appearance quality.

Dimensional Measurement:

Use appropriate measuring tools to inspect product dimensions, ensuring products meet design specifications.

Performance Testing:

Perform a series of performance tests on finished products, including strength, toughness, chemical resistance, etc., http://www.umbottle.com/ProductsDetail-VB-10332.htmlto ensure overall performance meets customer requirements.

Environmental Protection and Safety

Waste Management:

Properly handle waste generated during PCTG injection molding production to minimize environmental impact.

Worker Protection:

In injection molding production, ensure that operators wear suitable protective equipment to prevent exposure to potentially harmful chemicals affecting health.

By comprehensively addressing the above key issues, the PCTG injection molding production process can better ensure product quality, improve production efficiency, and ensure the safety and health of workers. http://www.umbottle.com/ProductsDetail-VB-10332.htmlEffective quality control and safety measures will give PCTG products a competitive advantage in the market.

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.