Can 5D printing in the water cup industry replace the water transfer, heattransferand water decal?

The application of printing technology in the manufacture of water cup patterns is also a matter of recent years.If I remember correctly, the market began to appear and gradually became popular in 2017.In 2018, the factory where Editor is located purchased two machines at the same time due to business needs. At that time, it was generally called "3D" printers in the market.However, due to the slow printing speed, the equipment is not durable, and the cost of consumables is high, the factory gave up this process after less than two years of use, and the printing equipment was also shelved in the warehouse.

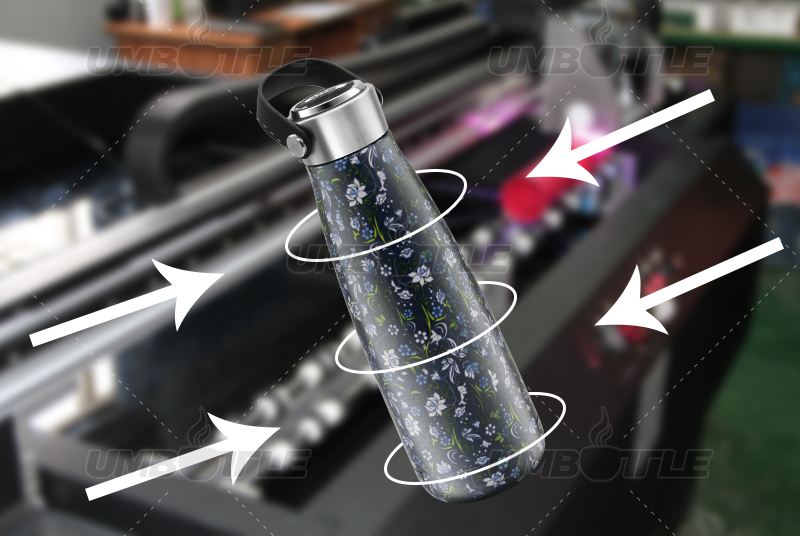

Since 2021, the printing technology has been qualitatively improved, and now it is called "5D" printing on the market, which not only improves the effect several times, but also reduces the cost of consumables required for printing.So can this process of 360-degree full-body printing on the water cup replace the thermal transfer, water transfer and water decal processes?

Friends who have been exposed to water cup printing know that among these manual processing printing methods, the cost of water stickers and water transfer printing is the highest, and the cost of thermal transfer printing is relatively low.At present, the cost of 5D printing for a full cup on the market is about 4-6 yuan. Many friends must have said that this price is an inappropriate substitute for water stickers and water transfer processes?

In addition, the work efficiency of the printer has been greatly improved (according to the editor, the current highest-speed printer can complete the 360-degree full-body printing of the water bottle in about 10 seconds), this understanding is indeed possible.But what the editor wants to say is that although printing has its existing advantages, the printing process cannot completely replace the water transfer, water sticker and thermal transfer processes at present.

1. The color of the printed pattern will be significantly different from that printed by the water sticker process. At the same time, no matter how high the precision of the current printer is, it cannot be compared with the printed flower film used in the water decal process.

2. It is due to the different ink brands and different standards of printers on the market. There are many brands of ink that fail to pass some tests such as the dishwasher test when used on water glasses.

3. Due to the arrangement of the nozzles of the printer, plane printing can only be achieved within a certain drop.It is impossible to achieve the printing of special-shaped water cups, and at the same time, it is impossible to achieve the natural transition of the pattern from the cup body to the bottom of the cup.

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.