What is the difference between roll printing and pad printing?

There are many processes for printing patterns on the surface of the water cup.The complexity of the pattern, the printed area and the final effect that needs to be presented determine which printing way is used.

These printing processes include roll printing and pad printing.Today, the editor will share with you the difference between these two printings based on our daily production experience.

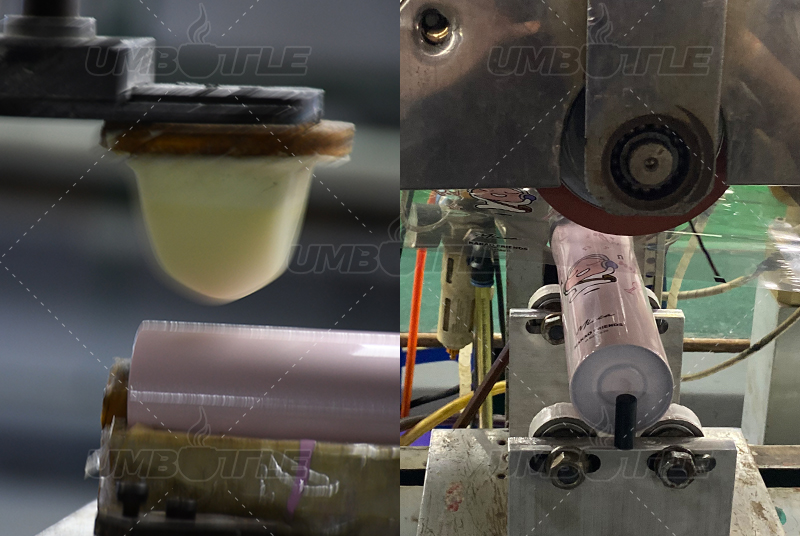

Rolling literally means rolling printing. Rolling here refers to the rolling of the water cup itself during printing, and the pattern on the printing plate is printed on the cup body by rolling.Roll printing is a kind of screen printing. The rolling printing process can increase the intensity of ink printing by controlling the screen plate of the screen, and finally present the desired effect.

At present, the roll printing machine used in most factories is monochrome.Monochrome roll printing machine can achieve one positioning but not two or more positionings.That is to say, it is difficult for a monochrome roller to print multi-color patterns because it cannot be registered.The color of the pattern after roll printing is usually high in saturation. After the pattern is dry, it will have a certain concave-convex three-dimensional feeling when touched by hand.

The pad printing process is more like a stamp.Pad printing is to transfer the ink covered by the pattern on the printing plate to the surface of the water cup through the rubber head.Due to the rubber head printing method, the density of the ink cannot be adjusted, and the ink layer of pad printing is usually relatively thin.

However, because the printing plate and the water cup are not fixed in the pad printing, the pad printing can complete precise positioning many times.Therefore, pad printing can be overprinted, or the same pattern can be printed with multiple inks of the same color to achieve the desired printing effect.

In water cup printing, one cannot simply assume that the same pattern must be printed with the same process.Which printing process should be used according to the shape of the water cup, the surface treatment process and the requirements of the pattern.

Dongguan Zhanyi Commodity Technology Co., Ltd. mainly produces stainless steel water cups and plastic water cups, and undertakes OEM and OEM of water cups for the world.Our company strictly abides by the industry's international standards, all materials need to have world food safety certification, and all production links implement product inspection systems.Global buyers are welcome to visit our official website, and we will have professional customer service staff to provide you with services online.