What are the misunderstandings in the production of water cups? (Four)

The editor continues to talk about some production misunderstandings about the printing process of the stainless steel water cup after spraying.

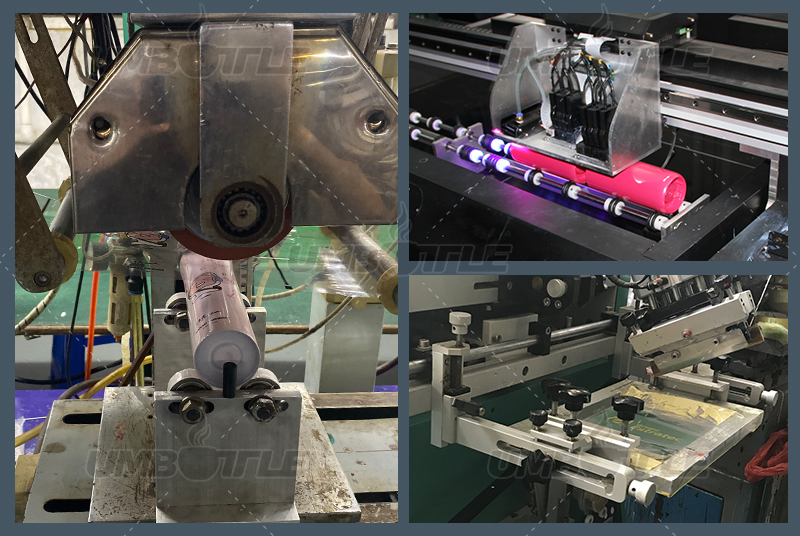

As consumers demand more and more requirements for the surface patterns of the water cups, manufacturers must be encouraged to continuously design and develop patterns, but different patterns have different effects and different spraying processes.The silk screen is suitable for spray paint effect and smooth powder spray effect on the water cup.Pad printing is suitable for water cups with spray paint effect and smooth powder spray effect.If it is a coarser sand grain powder, there will be more obvious burrs.The thermal transfer process can be used in both painting and powder spraying processes.

Water decals are similar to silk screen printing. They are only suitable for use on water cups with the effect of spraying paint and smoothing powder. The effect of coarse sand grains is not suitable.

Air transferprinting is the same as silk printing, but air transfer printing can also be used on the relatively finer sand grain powder that is sprayed.Water transfer printing can be used on spray paint and powdercoating, but when used on powder coating, it will be better to wait for the air transfer printing pattern to dry naturally before baking.

Dongguan Zhanyi Commodity Technology Co., Ltd. mainly produces various types of drinking utensils such as stainless steel water cups, plastic water cups and kettles.Our company has a complete automatic paint spraying and powder coating production line, which can be processed in customized colors according to customer requirements. As of December 2020, we have provided product innovation services to more than 200 customers around the world. Global buyers are welcome to visit our official website, and we will have professional customer service staff online to provide you with services.