The surface spraying process of stainless steel water cup is different, will the effect of laser engraving be the same?

With the increase in market demand, in order to meet the market and make products more differentiated, the water cup factory has continuously innovated the spraying process of the water cup surface, especially the stainless steel water cup. The surface of early stainless steel water cups only used ordinary paint. This method will cause the surface of the water cup to be resistant to friction, and after a period of use, the paint on the surface of the water cup will peel off.

As a result, various water cup factories continue to upgrade their technology and continuously improve the firmness of the water cup after the surface treatment process. Then pearl paint, texture paint, ceramic paint, hand-feeling paint, hand-feeling oil, rubber paint and plastic powder spraying appeared in the market. After continuous optimization, the spraying effect has been significantly improved, both in terms of wear resistance and the appearance of the sprayed surface effect.

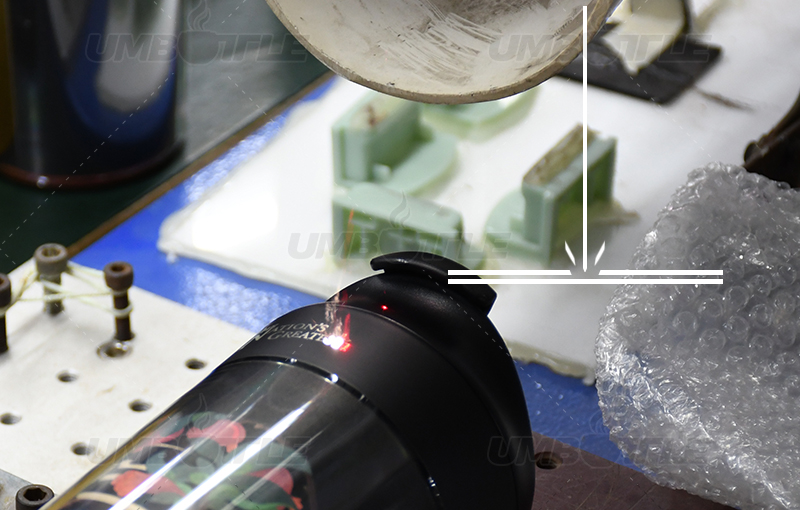

In recent years, laser engraving technology has been applied to the surface treatment of water cups. Usually, laser engraving technology is used to laser engrave graphics and various forms of logos on the surface of the water cup. Under various spraying processes, can laser engraving be able to maintain a consistent laser engraving effect on the water cups treated by different spraying processes?

The answer is obviously no. The stainless steel water cup with spray paint on the surface is relatively the most suitable for laser carving. Because the spray paint coating is relatively thin and the paint is hard after being baked at high temperature, the laser engraving high-temperature burning process can present a good graphic display effect. Due to the high viscosity, high hardness, and thick coating of the plastic powder coating, the laser engraving process is more difficult than the sprayed stainless steel water cup, and the low-power engraving will not penetrate and the high-power pattern will become black.

If stainless steel water cup is made of rubber paint and hand-feeling oil, laser engraving is not recommended. Due to the soft rubber paint and hand-feeling oil, low melting point and greater viscosity, it is difficult to ensure the integrity of the pattern after laser engraving. After high-power operation, although the pattern can be carved out by laser, there will be severe burn marks around the pattern, which is difficult to handle.

Before you decide to use the laser engraving process, please understand the power and operating instructions of the laser engraving machine, so that you can make better use of the laser engraving mechanism to make perfect graphics.

The thermos cup produced by Dongguan Zhanyi Commodity Technology Co., Ltd. uses sufficient materials and exquisite workmanship. In terms of material, we insist on using food-grade 304 stainless steel inside and outside, or a combination of 304 stainless steel outside and 316 stainless steel. The heat preservation time can reach 8 hours, and the cold preservation time can reach 12 hours. We insist on using the AQL1.0 inspection standard, which is far higher than the peer standards, and all links adopt a full inspection system to ensure that each product is a high-quality product. Customers from all over the world are welcome to visit our factory for inspection, and welcome to place orders for cooperation.