Why are the materials used in the molds of each process different when producing water cups?

Take the thermos cup as an example. The body of a stainless steel vacuum flask has to go through more than ten processes. These processes are different, the processing methods are also different, and the molds required for processing are also different.

Recently, a customer raised a question, probably because the other party consulted other factories to get the good performance of chromium 12, perhaps the other party’s factory deliberately highlighted and advertised chromium 12 to indicate that the mold developed by its own factory is good. So the customer asked us if we also use Chromium 12.

Our answer is that different parts molds use different materials, and only some parts use chromium 12. The other party asked us why we don’t use chromium 12 at all. Is it to reduce costs? Will the service life of the mold be lower?

It seems that the customer is fooled by the other's factory. The hardness of the chromium 12 material is indeed very high, and the material cost is relatively high, but it cannot be said that the high-cost and high-hardness material is suitable for the molds of all the accessories on the water cup. Due to different processing methods and different material performance requirements, the materials used in the mold in different processing procedures should first meet the mechanical value requirements of the procedures.

For example, when the cup is threaded, the hardness of the mold is extremely high, and it cannot be deformed due to long-term pressure. At this time, chromium 12 material is needed to make the threaded mold.

When the shell is reshaped or molded, because it has to withstand the huge pressure from the surroundings, the material needs to have excellent toughness and pressure resistance, and chromium 12 is obviously not enough. If chromium 12 is used because of its hardness, it is easy to cause mold cracking during production and processing. This requires the use of 45# steel inlaid tungsten steel, which can not only meet the production requirements but also increase the life of the mold.

Therefore, according to the technical requirements of processing, the use of suitable materials to make molds for different parts can not only produce products with stable performance, but also ensure the service life of the mold.

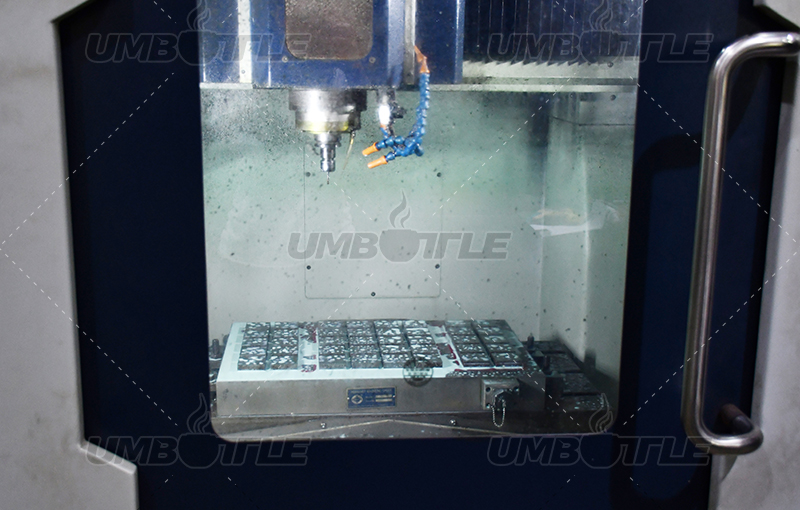

Dongguan Zhanyi Commodity Technology Co., Ltd. currently accepts the processing and production of stainless steel water cups and kettles. We have 1 complete stainless steel pipe drawing machine and 2 stainless steel water cup production lines. In addition to the pipe drawing machine, it also has expansion machines, stretching machines, punching machines, shaping machines, etc. At present, it has produced more than 80 kinds of different stainless steel water cups, including stainless steel business thermos cups, stainless steel sports water cups, stainless steel children's water cups, stainless steel coffee cups and so on. Global buyers are welcome to visit our official website, and we will have professional customer service staff to provide you with services online.