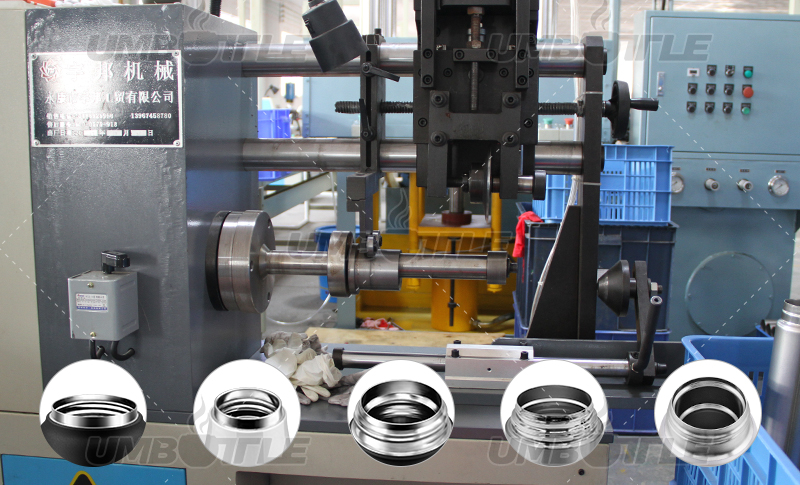

stainless steel water cups process--- thread rolling, What is thread rolling?

The thread rolling in the stainless steel water cup production process is also called screw or cup thread. Thread rolling is to process the mouth of a stainless steel water cup into a spiral thread. The thread rolling of the cup mouth is to match the cup lid for sealing and heat preservation. What is thread rolling?

The thread rolling processing method is to press and roll through the set thread mold, so that the cup thread is raised to form a continuous thread. During the thread rolling process, the pressure and the rolling speed play a key role.

Too much pressure will directly cause the cup mouth to rupture and deform, and too little pressure will cause the thread protrusion to be inconspicuous.

Too fast speed will cause inconsistent threads, unevenness, severely incomplete threads, too slow speed and too long pressure time will cause deformation of the cup mouth.

In the process of thread rolling, positioning is also very critical.

For some special cups that have strict positioning requirements, positioning fixtures need to be added. Otherwise, after screwing the lid of the produced water cup, it will be found that the positioning point of the lid is inaccurate.

The thermos cup produced by Dongguan Zhanyi Commodity Technology Co., Ltd. uses sufficient materials and exquisite workmanship. In terms of material, we insist on using food-grade 304 stainless steel inside and outside, or a combination of 304 stainless steel outside and 316 stainless steel. The heat preservation time can reach 8 hours, and the cold preservation time can reach 12 hours.

We insist on using the AQL1.0 inspection standard, which is far higher than the peer standards, and all links adopt a full inspection system to ensure that each product is a high-quality product. Customers from all over the world are welcome to visit our factory for inspection, and welcome to place orders for cooperation.