What factors should be paid attention to in the water cup injection molding process? (二)

Injection molding is a separate engineering technology whose purpose is to transform the raw materials of thermoplastics into products that can be used and maintain the original performance through the important process conditions of injection molding. Therefore, the preparation of process parameters for injection molding is an important part of ensuring injection molding processing.

The major factors that should be paid special attention to in the preparation of injection molding process parameters are: temperature, pressure, and time. The following is an introduction to the first element: Pressure.

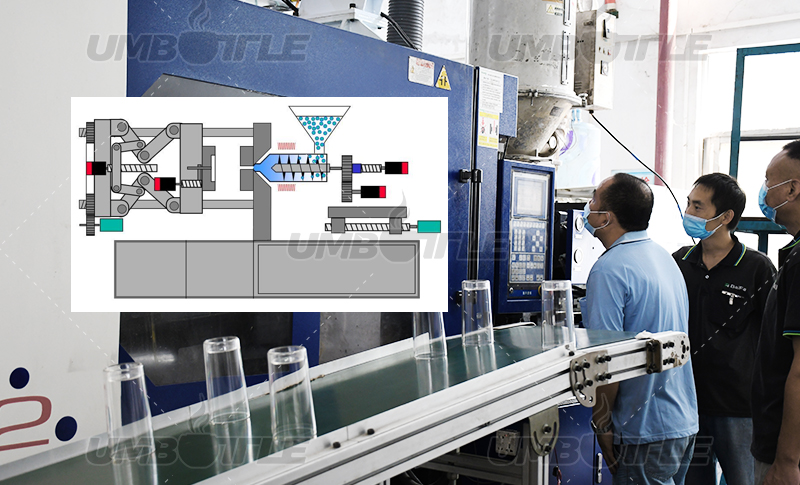

Pressure control during the processing of injection molded products includes two major processing processes: injection pressure and plasticizing pressure (ie, back pressure).

Among them, the injection pressure is transmitted to the end of the barrel through the hydraulic system of the injection machine (the electric injection machine uses a servo motor) to push the screw forward, that is, the pressure applied to the end of the screw is called the injection pressure.

In injection molding, the role of injection pressure is to overcome the molten plastic from the barrel to the mold cavity. The flow resistance during the filling process, the rate of melt filling and the compaction of the melt.

The plasticizing pressure refers to the pressure that the melt on the top of the screw is subjected to when the screw rotates and retreats. This is called plasticizing pressure, also known as back pressure. It can also be said to overcome the resistance caused by the rotation of the screw feed, called back pressure.

Under normal circumstances, a proper increase of the back pressure can make the melt temperature uniform, the color mixture uniformly, and the gas in the melt can also be discharged. In normal production operations, the back pressure should be as small as possible while maintaining good product quality.

Dongguan Zhanyi Commodity Technology Co., Ltd. currently has 44 single-color injection molding machines of different tonnage and 6 double-color injection molding machines of 360 tonnage. We can provide global users with the processing and production of plastic daily necessities and food and kitchen supplies, and we can also undertake various 3C peripheral injection products, such as mobile phone cases, computer keyboards, etc. Global buyers are welcome to visit our official website, and we will have professional customer service staff to provide you with services online.