How much is the cost difference between good quality and bad quality?

Customers often ask the same question, "Your products are of good quality, but the prices are also high." To express my personal views on this issue today, I may offend some unscrupulous colleagues.

But "high price" seems to be the answer to the fact, is it really high for consumers? Take the stainless steel water cup as an example, I will compare cost difference between good quality and bad quality of water bottle from the following points:

1.Material costs

When you buy stainless steel water cups, whether you hear from the product manual or from the publicity, they are all 304 stainless steel, so are they really 304 stainless steel? Regarding the cost of stainless steel, you can search the current price of stainless steel on the Internet, and you can see the real-time price just now. There are not only 304 models, but also others.

Then everyone compares the price of 201 stainless steel. At this time, you will find that 201 stainless steel is 20%-30% less expensive than 304 stainless steel. Some unscrupulous factories will use 201 stainless steel to pretend to be 304 stainless steel, and some factories will make the inner tank of the stainless steel water cup made of 304 stainless steel in order to wipe the edge ball, while the outer shell is made of 201 stainless steel, because the outer shell is often covered by painting and other processes. The person cannot judge for a while.

2. Product performance

The thermal insulation cups of the same capacity and similar models have very different thermal insulation performance. Why is this?

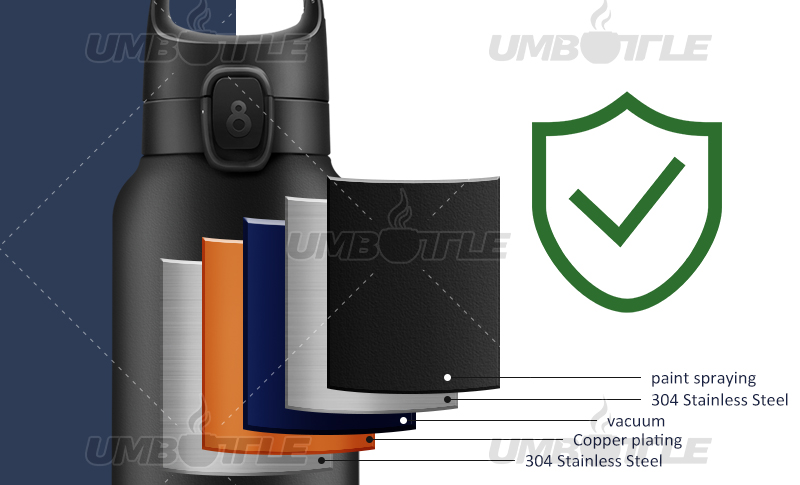

The heat preservation principle of the vacuum flask is to keep the air in a vacuum state by excluding the air in the two layers of stainless steel interlayer to keep it warm. In order to make the heat preservation effect better, the copper plating process will be done on the stainless steel inner wall in the interlayer. There are strict requirements on the thickness of the copper plating and the time of vacuuming. Some factories do not hesitate to reduce the vacuuming market in order to pursue profit, and even no longer use copper plating process for the inner wall. The cost of this approach is reduced, but the service life and quality of the product are greatly reduced.

3. Decreased quality index

The quality here includes all the accessories of a vacuum flask. A qualified vacuum flask needs to meet the collision test of the international standard, and there should be no deformation, paint peeling, etc. in the regulations. To meet such requirements, not only the materials must be strictly selected, but also the processing must be strictly required. For example, spray paint must be water-based environmentally friendly paint and high-adhesion paint, and the price of such paints is often higher. The painted water cup must be baked at a high temperature. The temperature must be baked at 160°C for 25 minutes to ensure that the paint is firmer.

Similarly, in order to pursue profit, many factories have replaced water-based paint with oil-based paint, and replaced high-adhesion paint with ordinary paint, turning high temperatures into low temperatures, and shortening the duration. In this way, the cost of painting the water cup will be greatly reduced, but there will be a phenomenon that the paint will fall off if you use your nails to scrape the paint slightly.

The above points are just a few outstanding points of the cost comparison in the production of stainless steel water cups, and the others will not be repeated one by one.

All water cups produced by Dongguan Zhanyi Commodity Technology Co., Ltd. are made of excellent raw materials certified by world-renowned institutions. All the water cups produced can meet the random inspection of customers. All products adopt the world AQL1.5 testing standard. Global buyers are welcome to visit our company's official website and contact sales personnel. We can provide you with the various certifications we have obtained.