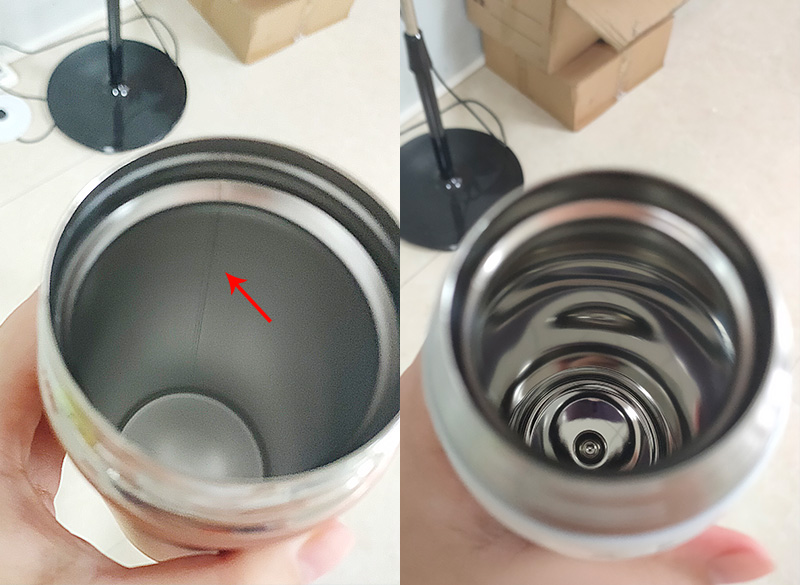

Will the welding line of the inner tank of the stainless steel vacuum flask affect the heat preservation time?

Stainless steel vacuum flask processing has different processes such as water swelling and stretching. Regardless of whether it is the terminal consumer market of the water cup or the B2B procurement market, there will be some doubts about whether the process of having a welding line in the water cup will affect the heat preservation time. So does a thermos cup with a welding wire in the inner tank affect the insulation time? Answer: Does not affect

The water swelling process is to form the tube through the laser welding process and then process it into the cup body by the water swelling process, so there will be laser welding lines inside. The stretching process is to process the body of the water cup in another way, without welding wires inside. The heat preservation performance of the water cup is controlled by the qualification of the processing technology and vacuum. The stainless steel vacuum flask produced by the qualified drawing process will not affect the thermal insulation of the water glass because of a laser welding line. If it is not insulated, it can only indicate that the wire bonding process is inadequate, indirectly or directly causing vacuum damage, which will cause poor insulation of the cup.

Although the welding wire does not affect the heat preservation of the water cup, it is still necessary to choose a water cup with a neat and delicate welding wire when purchasing. Rough and skewed welding wires are more likely to be unqualified products.

Dongguan Zhanyi Commodity Technology Co., Ltd. produces various capacity vacuum flasks, and has both water rising and stretching processes, which can meet the different requirements of customers in the global market. Buyers from all over the world are welcome to contact our salespersons to obtain samples, and welcome everyone to visit our factory.