What is the difference between the one-step method and the two-step method in the production of plastic water cups?

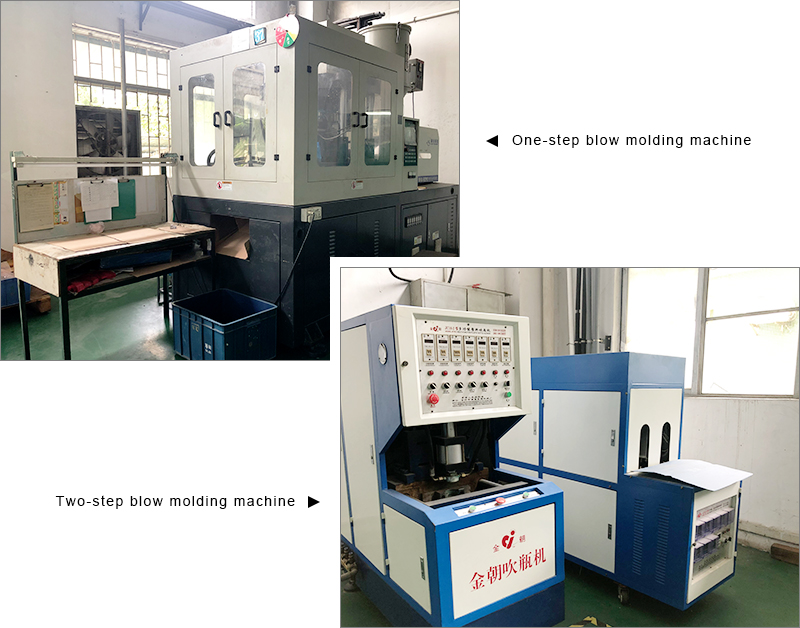

Recently, a customer asked about the difference between the one-step method and the two-step method in the production of plastic water cups? "One-step method" and "two-step method" refer to the operating mode of the bottle blowing machine. "One-step method" means to complete the entire plastic cup blowing process in one step, so it is called one-step method.

The "two-step method" refers to the production of plastic cups that need to be completed twice, so it is called the two-step method.

In terms of production quality, the product quality produced by the "one-step method" will be more stable than the "two-step method". The production efficiency will also be much higher than the "two-step method." But in terms of mold development costs, the cost of the "two-step method" will be lower. At the same time, in the production of products, the "two-step method" is easier to correct problems, reduce material costs, and is more suitable for the production and processing of small batch water cups because it is completed in two times.

Therefore, products with a large number of orders and high-quality pursuits are suitable for "one-step" production and processing, and products with a small number of products are suitable for "two-step" production.

Dongguan Zhanyi Commodity Technology Co., Ltd. also has "one-step" and "two-step" plastic water cup production equipment and technology, which can meet the needs of different plastic water cup orders in the global market. The plastic water cups produced have passed the international quality AQL2.5 standard, which is far higher than the industry standard. Buyers from all over the world are welcome to contact our salespersons to obtain samples. At the same time, we welcome everyone to visit our factory. We are willing to serve you wholeheartedly. To understand us, please visit http://www.umbottle.com