Why do some stainless steel vacuum cups use tin foil for the vacuum layer?

Why do some stainless steel vacuum cups use tin foil for the vacuum layer?

Answer: Play a heat preservation effect

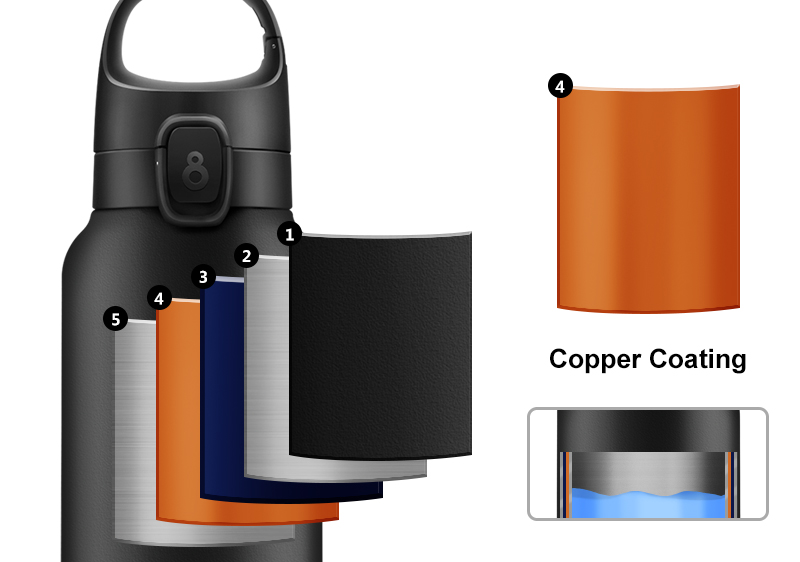

If the stainless steel water cup has good heat preservation effect, in addition to vacuum treatment, heat preservation coating is also required on the inner stainless steel. Usually the factory will use copper plating to improve the heat preservation performance of the water cup, because copper has good thermal conductivity, it can lock the temperature well in the vacuum interlayer and improve the heat preservation performance of the water cup.

However, in order to reduce production costs and to meet customer-specified requirements, some factories choose to use tin foil to wrap the stainless steel water cup interlayer, which can also play a role in improving thermal insulation performance. Because the tin foil is independent and cannot be completely attached to the outer wall of the inner tank, the tin foil will fall off inside the water cup after a long time, causing the cup to produce abnormal noises, which not only affects the insulation performance, but also causes users' troubles.

The stainless steel insulated water cup produced by Dongguan Zhanyi Commodity Technology Co., Ltd. uses copper plating on the inner layer, and the thickness of the copper plating is 0.1 mm-0.3 mm. Raise the copper plating standard and form the company's standardization requirements.

Buyers from all over the world are welcome to contact our salesperson to get samples, and at the same time, welcome everyone to visit our factory. We are willing to serve you wholeheartedly. To understand us, please visit http://www.umbottle.com