Does the Inner Layer of the Water Bottle Need to Be Electrolyzed?

Does the inner layer of the water bottle need to be electrolyzed?

Answer: No

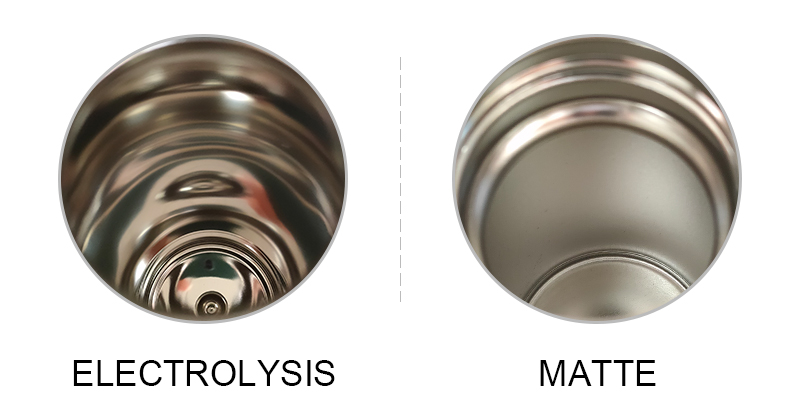

Before understanding whether the inner liner of a water bottle must be electrolyzed or not, first understand why many water bottle liners use the electrolysis process. The inner tank of a water bottle needs to be processed in multiple processes. When it is about to become a finished product, many of the inner tanks often have stolen goods, small particles attached to it and bruises during processing.

Electrolysis is to improve the particles on the metal surface through the combined action of the current of the positive and negative electrodes and the electrolyte, and reduce the surface roughness of the metal, so as to achieve the purpose of bright and smooth product surface.

Therefore, electrolysis is the fastest and relatively low cost process to improve the smoothness and brightness of the inner tank.

In addition to the electrolytic process of the inner tank, polishing can also be used to process the inner tank. However, due to the different shapes of the water cups, some water bottle have irregular shapes affected by their functions, which poses a greater difficulty to the polishing technology and cannot be polished. Electrolysis is ultimately used.

Dongguan Zhanyi Commodity Technology Co., Ltd. produces stainless steel water cups of various types, capacities and functions. Electrolysis or polishing technology can be used for the inner tank according to product characteristics and customer requirements. Buyers from all over the world are welcome to contact our salespersons to obtain samples. At the same time, we welcome everyone to visit our factory. We are willing to serve you wholeheartedly. To understand us, please visit http://www.umbottle.com