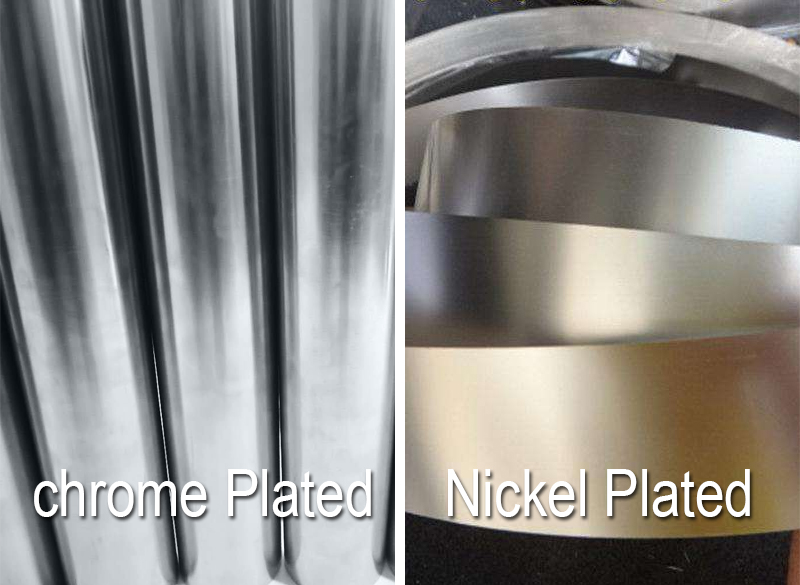

When Electroplating the Product Appearance, Should I Use Chrome Plating or Nickel Plating?

For product appearance plating, in order to satisfy the visual and functional functions, chrome plating is generally used? Or nickel plating?

There is a big difference between the performance of chromium plating and nickel plating after electroplating products.

In terms of corrosion resistance, the nickel-plated layer is higher than the chromium-plated layer, and the ductility of the material and the fusion with the product are higher than the chromium-plated treatment.

However, the cost of nickel plating is also higher than that of chromium plating in terms of production costs.

In terms of wear resistance, the chromium plating layer is higher than the nickel plating layer.

The cost in processing is also relatively low, and it has a relatively good cost performance.

Chrome plating is currently the most used chrome treatment on the market.

Dongguan Zhanyi Commodity Technology Co., Ltd. can provide chrome plating and nickel plating processing services according to customer requirements. In addition to the electroplating process, it can also process thermal transfer, UV plating and other processes. Customers from all over the world are welcome to ask us for samples for evaluation. Welcome to our factory for inspection, and welcome to place orders for cooperation. To understand us, please visit http://www.umbottle.com